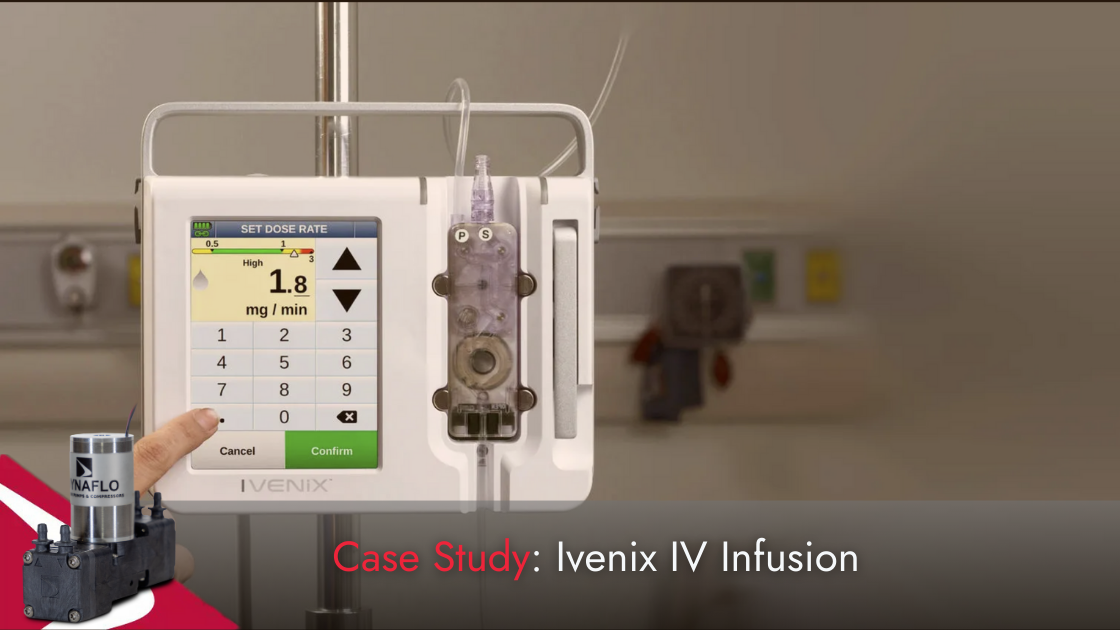

Case Study: Mini Diaphragm Pump for Ivenix Drug Infusion System

The goal of Ivenix’s patented new technology was to revolutionize drug infusions and solve significant issues associated with drug delivery in U.S. hospitals.

The technology requires short bursts of pneumatic pressure to actuate a diaphragm-based drug delivery system with a disposable cartridge. (The drug is isolated from the pump creating the pneumatic bursts).

Requirements

Ivenix needed a small, high-performance air pump to generate the short bursts of pneumatic pressure and a vacuum to drive their infusion pump. They tested “stock, off-the-shelf” diaphragm pump samples from several suppliers, including the 2000 Series miniature pump from Dynaflo, Inc. The critical diaphragm pump performance evaluation criteria included:

- Size

- Time-to-vacuum

- Time-to-pressure

- Cost

- Reliability

Trials

Early testing revealed several technical challenges and shortcomings from all potential suppliers, including the ability to restart under pressure and premature failures of brush motors.

Ivenix realized they needed a customized solution for their specific technical challenges. Whereas other suppliers offered minimal variants, such as eccentricity/stroke and motor, Dynaflo was able to take all of their challenges into consideration and develop a completely new design.

Development

Ivenix began a multi-year development program with Dynaflo to create an entirely new, dual-head, 4-valve-per-head high-performance pump: the 6000 Series.

The 6000 Series features two diaphragm pump “heads” driven by a central brushless D.C. motor. One head is used for vacuum and the other for pressure. These outputs are used with valves and related electronics to precisely control the flow of drugs through the patented cartridge of the infusion mechanism.

Dynaflo’s ability to provide quick design iterations and 3D-printed prototypes enabled Ivenix to forge ahead with the patented technology and produce its revolutionary drug delivery system.

Collaboration

“Speed of development and prototyping, partnership, and collaboration were all key factors when working with Dynaflo,” said Ben Powers, Vice President.

Together, Ivenix and Dynaflo tackled technical challenges to develop reliable solutions for the construction, valves, diaphragms, and motors – to withstand the electrical and mechanical issues associated with thousands of short-burst (~100ms) on/off cycles during the accelerated life cycle testing.

Our ability to work quickly together helped bring the multi-year development cycle to a successful product introduction in 2020.

“Dynaflo stuck with us when others would have walked away.”

Customization – Not Configuration

Customization – not “configuration” of standard bits and pieces – is the key to Dynaflo’s contribution to customer success.

Contact Us to find out how a Dynaflo pump can bring your product to the forefront of technology.