Efficient operation with low power consumption

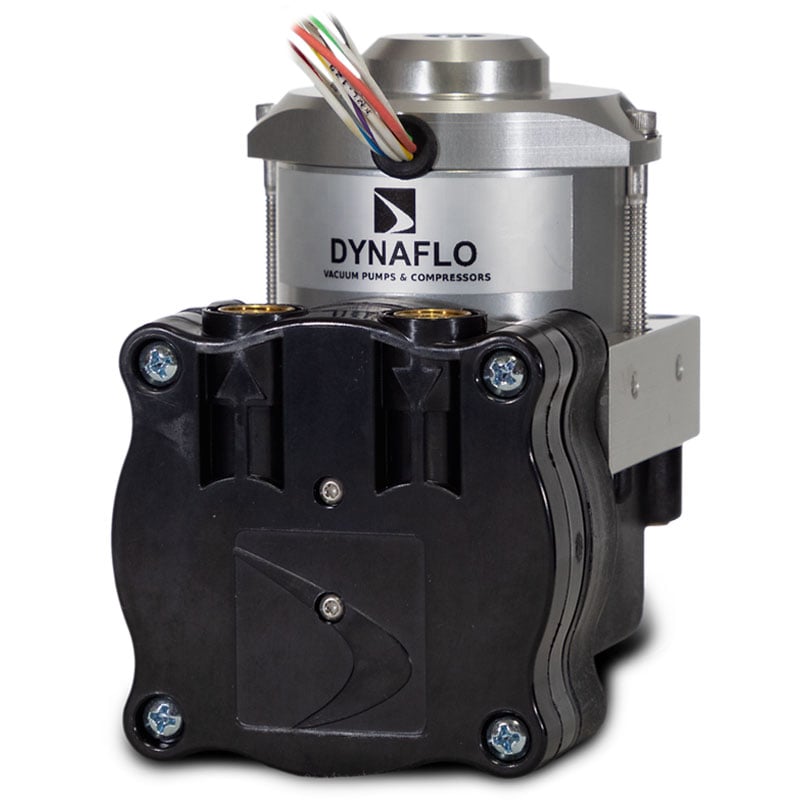

The 1000 Series are small, powerful, and fully customizable diaphragm pumps that use ½ the power of leading pumps. Use them in pressure or vacuum products like air sampling, catheter cleaning, medical aspirators, and vacuum lifters.

| Max Flow | 75 L/min (2.6 cfm) |

| Max Pressure | 40 psig (2.8 bar) |

| Max Vacuum | 28 inHg (70 mbar abs) |

| Operating Voltage | 12 VDC or 24 VDC |

| Price Range | Call for Pricing |

Why customers love the 1000 Series

Our customers tell us these diaphragm pumps are the right mix of size, weight, power, and price.

Why you will love this pump

The 1000 Series is 60% more efficient than leading pumps—and the motor has a minimum life of 1,000 hours to reduce the time your customers spend replacing batteries.

The largest dual head 1000 Series diaphragm pump is ~5.81 x 4.75 in (14.76 x 12.07 cm). Their small size makes them easy to integrate into smaller products and compact spaces.

The largest pump weighs around 2.9 lbs (1.3 kg), making the 1000 Series diaphragm pumps ideal for portable applications that require a lightweight solution.

Designed and built in the United States with high-quality, precision materials and a strong focus on safe, reliable performance. These diaphragm pumps also restart under load so target vacuum levels are maintained.

Dynaflo uses high-quality materials for the valve, diaphragm, and bearings—and a motor with a minimum life of at least 1,000 hours— to maximize the life of your battery-powered products in any environment.

Oil-free diaphragm pumps require significantly less maintenance than pumps that require oil. And when maintenance is needed, replacement parts are readily available and easy to get to and replace.

Typical Specifications

Dynaflo, Inc. tailors each pump to meet your unique requirements, test conditions, and packaging upon request. These are common specifications for the 1000 Series diaphragm pumps.

38 L/min Diaphragm Pump

| Max Flow | 38 L/min (1.3 cfm) |

| Max Pressure | 18 psig (1.2 bar) |

| Max Vacuum | 24 inHg (200 mbar abs) |

| Motor Options | Brushed or Brushless DC |

| Operating Voltage | 12 VDC or 24 VDC |

|

Max Current Draw |

3.0 A |

| Ambient / Media Temp | 41° F to 104° F (5° C to 40° C) |

| Weight | 2.5 lb (1.1 kg) |

| Head Material | PPS or custom |

| Diaphragm Material | Neoprene or custom |

| Valve Material | Silicone or custom |

| Port Orientation | Side-by-side or in-line |

| Wire / Connector | Flying lead or custom |

| Price Range | Call for Pricing |

75 L/min Diaphragm Pump

| Max Flow | 38 or 75 L/min (1.3 or 2.6 cfm) |

| Max Pressure | 40 or 18 psig (2.8 or 1.2bar) |

| Max Vacuum | 28 or 24 inHg (70 or 200 mbar abs) |

| Motor Options | Brushed or Brushless DC |

| Operating Voltage | 12 VDC or 24 VDC |

|

Max Current Draw |

4.5 to 6.0 A |

| Ambient / Media Temp | 41° F to 104° F (5° C to 40° C) |

| Weight | 2.9 lb (1.3 kg) |

| Head Material | PPS or custom |

| Diaphragm Material | Neoprene or custom |

| Valve Material | Silicone or custom |

| Port Orientation | Side-by-side or in-line |

| Wire / Connector | Flying lead or custom |

| Price Range | Call for Pricing |

Create your competitive edge

Looking for unique performance capabilities or innovative features that no one else has to give you a competitive edge? Dynaflo, Inc. offers customization services and complimentary diaphragm pump trial periods to help you stand out from the crowd. We can adjust size, performance, motor, and mechanical options to fit your precise requirements. The most requested customization features include:

- Fit-for-purpose motor type and performance

- Port configuration to minimize tubing

- Material options for diaphragms and valves

- Custom eccentrics for targeted flows

- Specialized wiring and connectors

- Distinct mounting specifications

- White labeling to provide uniqueness to your product

Building the perfect product together

Dynaflo, Inc. understands the importance of getting your products to market quickly. We provide skillful and confidential guidance throughout all phases of diaphragm pump development to create pumps that seamlessly integrate into your products and provide you with added value.

We work with your engineers and product managers to discuss the current market requirements your product must meet and the features that will delight your customers. We use this information to determine your product's proper flow rate, cycle time, power, and vacuum/pressure levels.

We provide complimentary trial periods for pumps that meet your specifications so you can quickly test and evaluate how the pump will perform in your product. We then work together to determine if modifications need to be made to the pump's standard specifications to ensure it meets all your requirements, mounts quickly, and is easy to maintain.

If changes are required, Dynaflo's engineering will fine-tune the size, performance, motor, and mechanical options of the pump to fit the precise requirements of your product.

We inspect and test 100% in line with your requests before sending your diaphragm pump for final testing in your products.

Once all tests have passed, we ship your diaphragm pumps and spare parts. It is important to us to minimize the overall running costs of our diaphragm pumps, and we take this into account in the pricing of our pumps and replacement parts.

Our partnership doesn't end once you have your pumps. After your products are in use, we will reach out to collect your feedback and evaluate how the diaphragm pumps are working for you. As the market changes and new needs develop, we respond with innovative, suitable solutions.

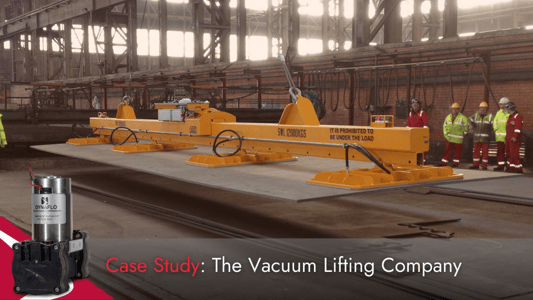

"We've been using Dynaflo, Inc.'s 1000 Series diaphragm vacuum pumps since 2002. They are ideal for us because they are small, lightweight and compact. We recommend Dynaflo diaphragm pumps because they are reliable with great performance."

Paul Watson The Vacuum Lifting Company

Learn More

Case Study: Mini Pump Powers Tisch’s Market-Leading Air Samplers

Tisch Environmental, Inc. (TEI) has been a leading manufacturer of air sampling equipment used to monitor air quality and particulate matter level for over 60 years. The founders, Wilbur Tisch and...

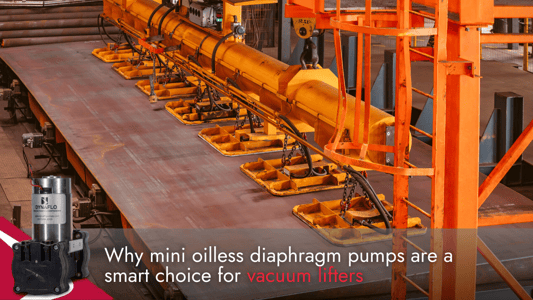

Why Mini Oilless Diaphragm Pumps are a Smart Choice for Vacuum Lifters

When it comes to improving the safety and reliability of vacuum lifters, the solution might be smaller and simpler than you think. Unlike the more complex or bulkier options, mini oilless diaphragm...

What is the best gas diaphragm vacuum pump for vacuum lifting?

If you're in the vacuum lifting business, chances are your product needs to be designed to be fast, reliable, efficient, and safe. Of course, this points straight to the heart of the system— the...

How to choose the right motor for your diaphragm pump

You've decided you need a diaphragm pump for your new or existing product. How do you make sure the one you choose has the right motor? This is a big decision because the motor is almost always the...

How a Custom Dynaflo Pump Helped Create Safer Vacuum Lifters

For The Vacuum Lifting Company, safety and eliminating damage are top priorities. Since 1999, they have manufactured battery and AC-powered vacuum lifters that increase operator safety and reduce...

Let's create your diaphragm pump

Every product is different, and some are one of a kind. We’re excited to hear about your products and how Dynaflo, Inc. can provide you with a competitive edge.