Give your products a competitive edge

Dynaflo's energy-efficient gas diaphragm vacuum pumps and air compressors are the right mix of size, weight, power, and price — and are custom-designed to meet your unique needs.

Our custom diaphragm pumps power cutting-edge products such as medical devices, air/gas monitoring devices, vacuum lifters, food & packaging, and high-precision devices.

Most popular diaphragm pumps

Custom mini diaphragm pumps designed for your unique applications

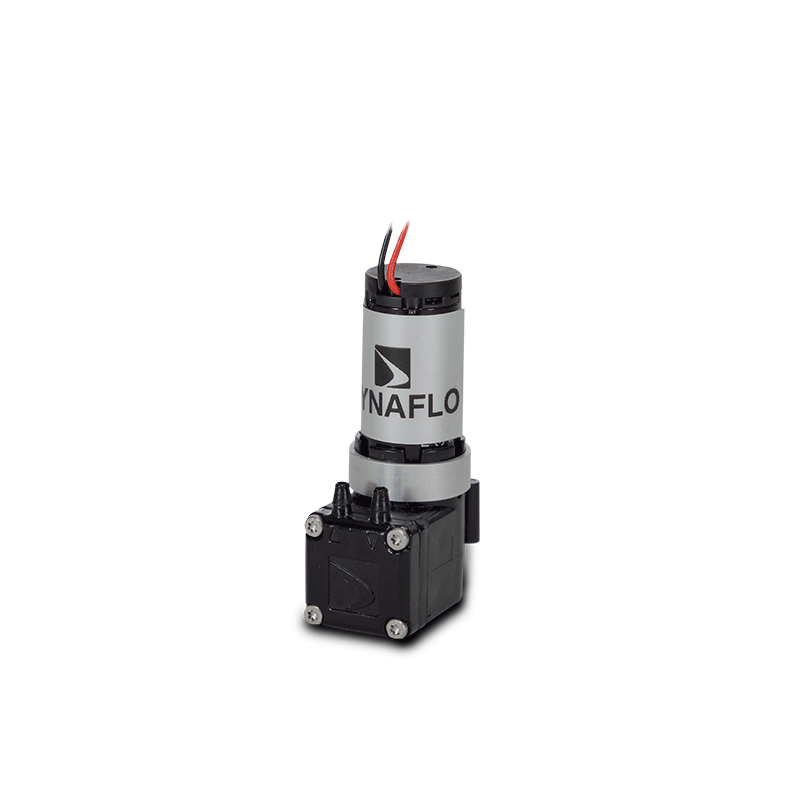

Suction Machine Diaphragm Pumps

Your suction machines need to rapidly clear airways while optimizing patient safety. Dynaflo’s diaphragm vacuum pumps deliver high performance with low power consumption, making them ideal for portable suction machines. This allows healthcare professionals to prioritize patient safety by balancing strong removal capabilities with the gentleness required for delicate tissues.

Mechanical Ventilator Diaphragm Pump

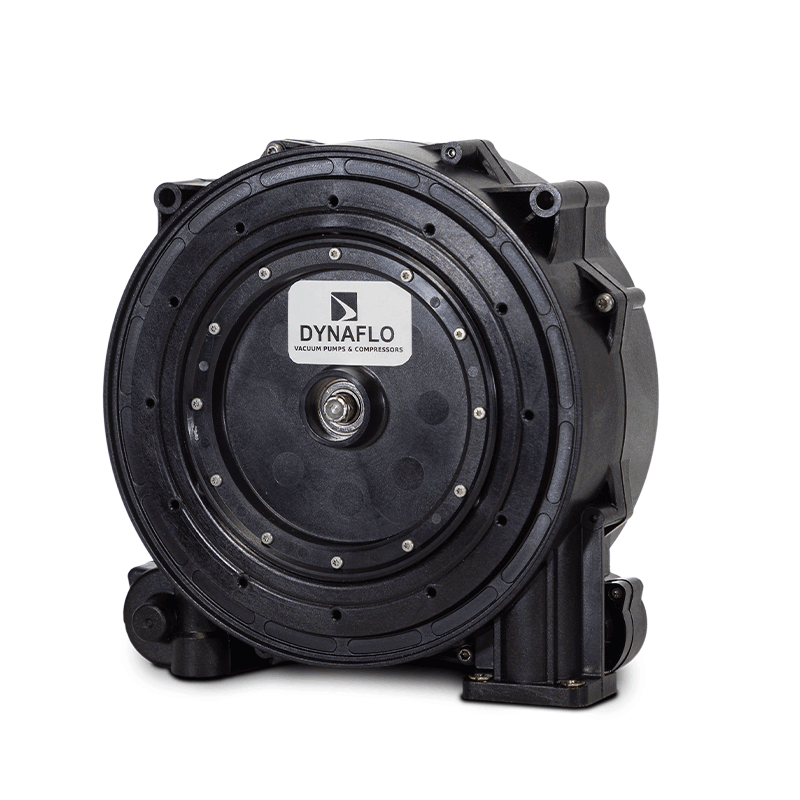

Provide high-performance, pulse-free ventilation to respiratory patients in demanding EMS, military, and medical transport environments. Dynaflo, Inc.’s 3000 Series "Radial 12" smooth flow diaphragm pumps provide high performance, low pressure, and the only real smooth output flow on the market so your ventilator can carefully control airflow to patients.

Prosthetics Diaphragm Pumps

The diaphragm pump is the heart of your suction-based prosthetic devices. It needs to reach a high vacuum within seconds, be able to start back under load, run on a small battery for hours, and fit into a tiny space. Given the potentially harsh conditions associated with creating vacuum suction near the human body, it is also essential to be able to refurbish the pump while re-using the motor.

Drug Infusion System Diaphragm Pumps

When it comes to revolutionary drug infusion systems, you need a pump that can generate short bursts of pneumatic pressure and a vacuum to drive infusion pumps and precisely control the flow of drugs. Critical diaphragm pump performance criteria for drug infusion systems include time-to-vacuum, time-to-pressure, cost, and reliability. The 6000 Series Mini Pump has four valves, so it's good for high flow—and meets critical FDA criteria for drug infusion systems.

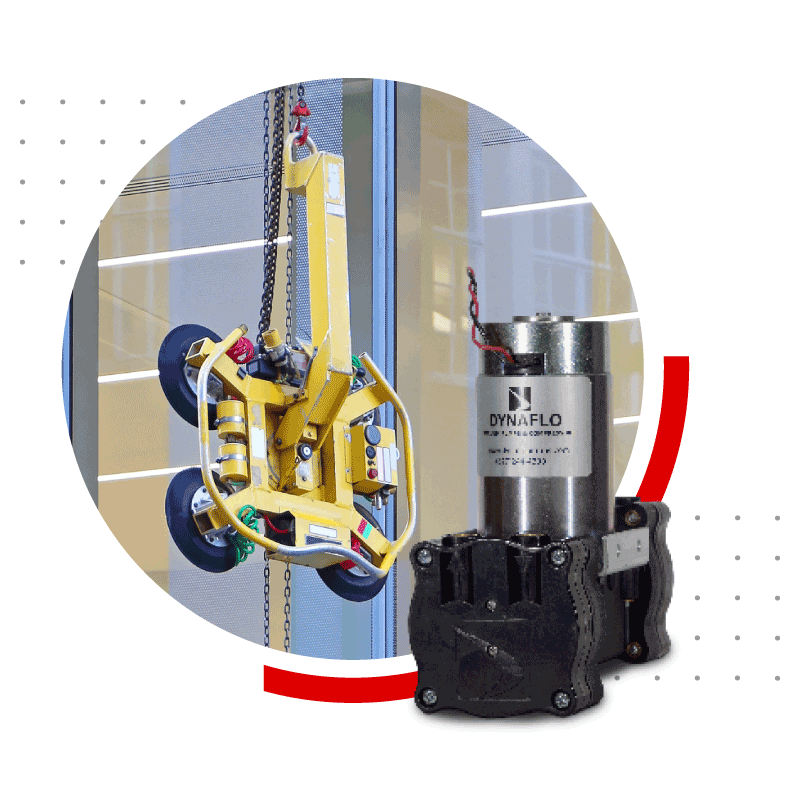

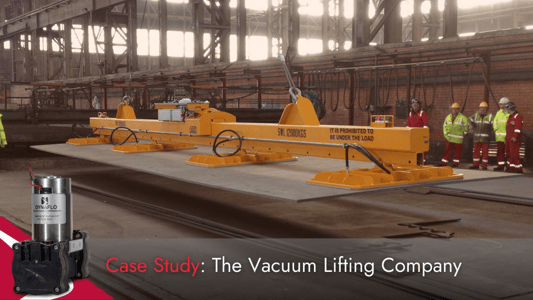

Vacuum Lifter Diaphragm Pumps

Your vacuum lifters need to increase operator safety while maximizing productivity. Dynaflo's 1000 Series are small, lightweight, and powerful diaphragm pumps that use about ½ the power of leading pumps. Because of their size, you can fit 1-2 diaphragm pumps in smaller lifters or compact spaces and up to 20-30 for larger lifters.

Recent diaphragm pump articles

Why Mini Oilless Diaphragm Pumps are a Smart Choice for Vacuum Lifters

When it comes to improving the safety and reliability of vacuum lifters, the solution might be smaller and simpler than you think. Unlike the more complex or bulkier options, mini oilless diaphragm...

How to Change the Diaphragm in a Gas Diaphragm Pump

Welcome to our latest insight on maintaining your gas diaphragm pumps. Today, we'll focus on replacing the diaphragm in a gas diaphragm vacuum pump.

How Dynaflo Tests IV Infusion Micro Pumps for Flawless Performance

The 6000 Series is a high-performance diaphragm pump that drives the mechanism in an automated IV infusion system. The actual drug doesn't go through this pump but is used to drive the mechanism for...

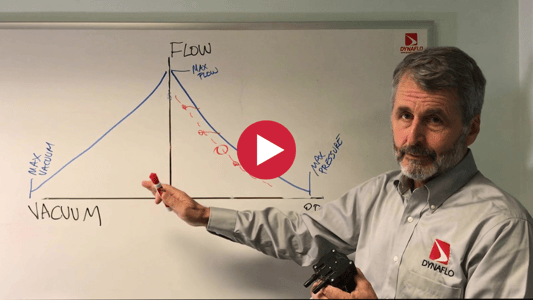

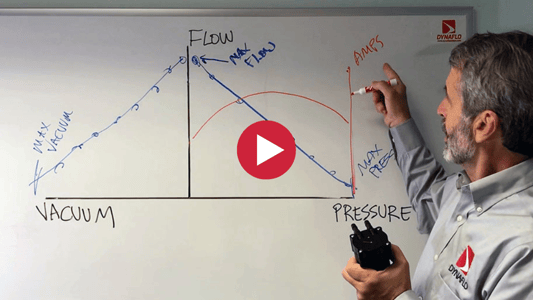

How to properly asses the performance of a diaphragm pump

What is listed for max flow and max pressure isn't really what you should look at when assessing the performance of a diaphragm pump. Why?

How to graphically the performance of a diaphragm pump

It is important to understand diaphragm pump performance, and be able to measure this performance as well. In order to show the performance of a diaphragm pump, we must create a graphical...

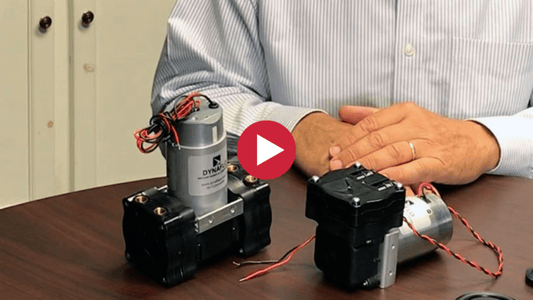

Which is better? A flat or convoluted diaphragm?

There are evident differences between a flat and convoluted diaphragm, and there are different scenarios where one diaphragm might be better than another for your diaphragm pump.

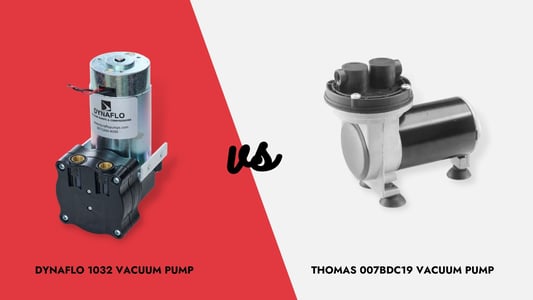

What is the best gas diaphragm vacuum pump for vacuum lifting?

If you're in the vacuum lifting business, chances are your product needs to be designed to be fast, reliable, efficient, and safe. Of course, this points straight to the heart of the system— the...

When is a custom diaphragm pump the best option?

When you're looking for a diaphragm pump, it is vital that the pump is the right fit for your application and works well with your mechanical design. Does this mean you need a custom pump? Not...

How does a diaphragm pump work?

In today's Rapid Insight, we will review how diaphragm pumps work. So, how does a diaphragm pump work?

How to choose the right motor for your diaphragm pump

You've decided you need a diaphragm pump for your new or existing product. How do you make sure the one you choose has the right motor? This is a big decision because the motor is almost always the...

How a Custom Dynaflo Pump Helped Create Safer Vacuum Lifters

For The Vacuum Lifting Company, safety and eliminating damage are top priorities. Since 1999, they have manufactured battery and AC-powered vacuum lifters that increase operator safety and reduce...

Vacuum Lifter Diaphragm Pump Selection Guide | Dynaflo, Inc.

Selecting a vacuum pump for your battery-powered materials handling vacuum lifter is an important decision. It’s likely the single most expensive component in your vacuum lifter. It can affect its...

Honda Helps Dynaflo Manufacture Pumps for Medical Ventilators

Prior to March 2020, Dynaflo, Inc. was building the 3000 “Radial 12” Compressor for a ventilator manufacturer at the rate of about 75 units per week.

The COVID-19 crisis of early 2020 caused a surge...

What is the Most Efficient Mini Diaphragm Vacuum Pump?

Manufacturers of battery-powered equipment prefer low-power diaphragm vacuum pumps and compressors because operators can use them on a single charge for an extended period. The most critical factor...

Case Study: Mini Diaphragm Pump for Prosthetics | Dynaflo Pumps

Artificial limbs, legs in particular, typically require straps or otherwise cumbersome attachment mechanisms to keep them in place. These straps can be uncomfortable and a real nuisance.

Let's create your diaphragm pump

Every product is different, and some are one of a kind. We’re excited to hear about your products and how Dynaflo, Inc. can provide you with a competitive edge.